Are robots coming to take your job? Yes, you should be concerned if you work at a BMW plant in California. Well, jokes aside. California’s Figure Robotics startup has partnered with BMW to deploy its versatile robots in the automaker’s Spartanburg, South Carolina facility. For what? To manufacture various BMW models, including the X3, X4, X5, X6, X7, and XM series.

Are Robots Taking Away Jobs?

BMW’s Spartanburg plant, which employs approximately 11,000 individuals, holds the distinction of being the largest automotive exporter in the U.S. in terms of value. Over the next 12 to 24 months, the humanoid robots will be seamlessly integrated into various manufacturing areas such as the body shop, sheet metal, and warehouse. Still, the exact quantity of robots set to be deployed remains undisclosed. The implementation will commence with a limited number and expand based on meeting performance objectives.

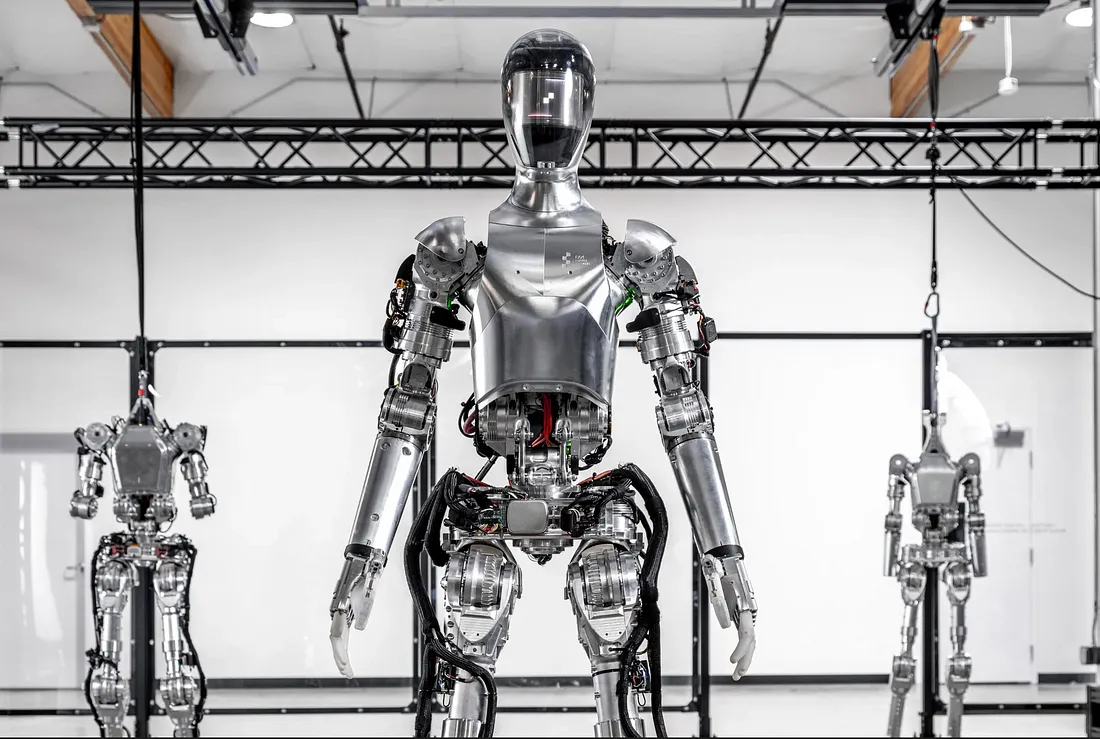

How is it going to work? Well, Figure 01 robot will initially automate tasks, freeing human workers for more complex roles. This will boost production efficiency. A recent YouTube video demonstrates the robot’s capabilities and ability to learn tasks like making coffee using AI. Figure chose a humanoid design for its robot to ensure compatibility with various tasks and environments.

Figure 01 combines the flexibility of human-like dexterity with cutting-edge AI capabilities. This makes it a versatile solution for various industries, including manufacturing, logistics, warehousing, and even retail. Initially, it will perform basic tasks like loading, unloading, and item movement at the Spartanburg facility. However, its learning ability will enable it to expand its skill set over time.

Brett Adcock, Figure’s CEO, highlighted the untapped potential of general-purpose robotics, emphasizing the benefits they bring regarding increased productivity, cost reduction, and enhanced safety.

What’s Next?

In addition to deploying Figure 01, BMW and Figure plan to explore other solutions for automotive production and beyond. BMW Manufacturing’s CEO, Engelhorn, reaffirmed their commitment to integrating innovative technologies for industry leadership. The number of deployed robots hasn’t been confirmed, but the plan is to have the first one operational within a year.

By the way, Figure is not alone in its endeavor to transition general-purpose robots from the lab to real-world applications. Another notable player in this field is Apptronik, a robotics company supported by NASA. In August 2023, Apptronik introduced Apollo, which is touted as the “most capable” humanoid robot to date. They intend to begin testing production models of Apollo in 2024 and eventually make it available for commercial use by late 2024 or 2025.

At UnioTech, we’re closely monitoring these advancements in humanoid robotics. Especially the way, as they pertain to hardware and integrated software. Utilizing technovation like ‘Figure 01’ in manufacturing represents both an automation leap and a major advancement in embedded systems. Which is aligning with our expertise in developing and integrating such technologies.